Lithium Deposits In India: 5.9 million tonnes Lithium deposits found in J&K: Why it’s important | India News

Lithium Tales

Lithium (Li) was first recognised as an element in 1817 when Swedish chemist Johan Arfvedson analysed the mineral petalite. “The metal itself was first isolated in useful quantities in 1855. In 1869, Dmitiri Mendeleev correctly positioned it adjacent to sodium, with the alkali metals, in his then revolutionary periodic table of the elements,” as per the US Geological Survey (USGS).

With a specific gravity of 0.534, it is about half as dense as water and the lightest of all metals. In its pure elemental form it is a soft, silvery-white metal, but it is highly reactive and therefore never is found as a metal in nature.

“Lithium has an average concentration of 20 parts per million in the Earth’s continental crust. It is more abundant than some of the better-known metals, including tin and silver. Lithium occurs in most rocks as a trace element, with the lithium substituting for magnesium in common rock-forming minerals,” USGS says.

India Reserves: “Inferred Resources (G3)”

Most of us are now familiar with lithium — what with its uses ranging from mobile phones and laptops to electric vehicles? But before getting into where India stands, how this lithium from J&K can be used and more, it is important to understand one thing from the GSI statement. “Inferred Resources (G3)”.

Inferred Resources means “part of a mineral resource for which tonnage, grade and mineral content can be estimated with a low level of confidence. It is inferred from geological evidence and assumed but not verified geological and/or grade continuity.

The United Nations Framework Classification for Fossil Fuel says that with the exception of past production that may be measured, quantities are always estimated and there will be a degree of uncertainty associated with the estimates.

This uncertainty is communicated either by quoting discrete quantities of decreasing levels of confidence (high, moderate, low).

“A low estimate scenario is directly equivalent to a high confidence estimate (G1), whereas a best estimate scenario is equivalent to the combination of the high confidence and moderate confidence estimates (G1+G2). A high estimate scenario is equivalent to the combination of high, moderate and low confidence estimates (G1+G2+G3),” UN says.

The G4 class, for instance, means the project is still at an exploratory stage. And according to the union ministry of mines & coals, here’s what India has been doing in the past few years:

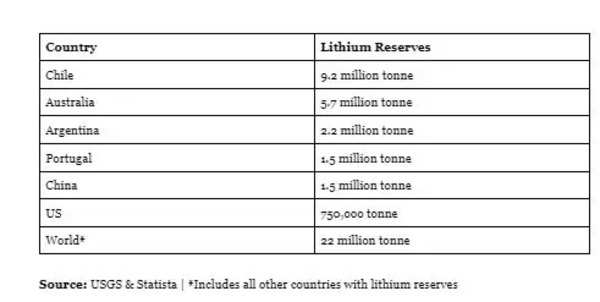

Global Reserves

According to the US Geological Survey (USGS) Mineral Commodity Summaries, 2022: Identified lithium resources globally have been revised to 80 million tonne. However, reserves from which the element can be accessed as on date is pegged at just over 22 million with Chile leading the table (9.2 million tonne).

While the USGS break-up of data does not include the reserves in China, Statista, a global company specialising in market and consumer data, pegs it at 1.5 million tonne.

Lends Itself To Many Uses

While lithium has many uses, the most prominent is in batteries for cell phones, laptops, and electric and hybrid vehicles.

Some key uses as per USGS include: Lithium added to glasses and ceramics for strength and resistance to temperature change; used in heat-resistant greases and lubricants, and it is alloyed with aluminium and copper to save weight in airframe structural components.

“Lithium is used in certain psychiatric medications and in dental ceramics. The lighter of two lithium isotopes — 6 Li — was used in the production of tritium for nuclear weapons,” USGS says.

But the use with the greatest potential benefit to the most people in the world is in rechargeable batteries. These batteries take advantage of lithium’s light weight and high electrochemical potential and make it possible to power cars and trucks by using renewable, carbon-neutral sources of energy (for example, solar, hydro, or wind) instead of gasoline or diesel.

Lithium-ion Batteries & India

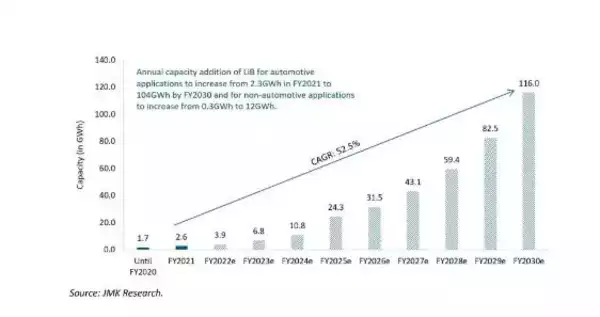

The introduction of Lithium-ion Batteries (LiB) has revolutionised numerous sectors, most prominently the EV industry. The adoption of LiB is accelerating in India and JMK Research — a specialist consultancy firm specialising in renewable energy — estimates that the annual LiB market in India will reach 116GWh in 2030, with EVs accounting for around 90% of the overall market on the back of huge government targets of adding variable renewable energy sources to the grid.

Key Players In India

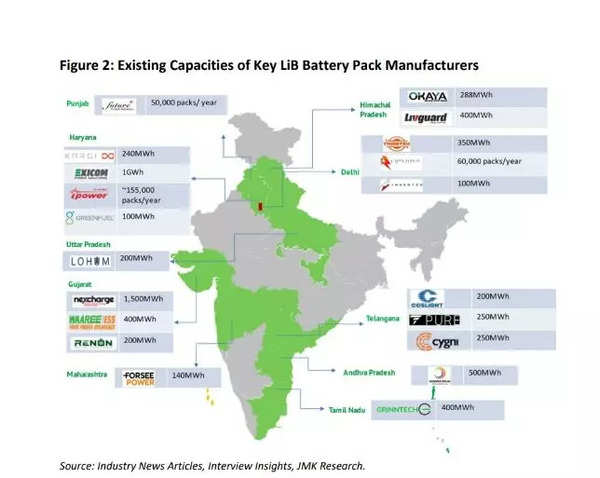

Of the total cost of LiBs, cells account for 65%, the battery pack 15%, BMS (battery management system) 15%, and the balance being the outer box, as per JMK Research.

So far, battery packs and associated BMS manufacturing have entirely dominated the space in India and Indian manufacturers are able to produce most of the sub-components that go in a battery pack while thermal pads still need to be imported.

Similarly, BMS and outer box are also primarily supplied by the Indian battery pack assemblers. “However, since India does not have BMS manufacturing components, it sources pre-programmed protection circuit boards (PCB) from China and undertakes printing in India. The LiB pack manufacturing market in India is fragmented and comprises numerous active players including Coslight India, Okaya, Exicom, followed by Trontek, Amptek, Cygni, Grinntech, Lohum Cleantech, Pure EV etc.

In what was the first for the country, the Indian Space Research Organisation’s (Isro) Vikram Sarabhai Space Centre (VSSC) successfully developed and qualified lithium ion cells of capacities ranging from 1.5Ah to 100Ah.

This was for use in satellites and launch vehicles and Isro, after successful deployment of the indigenous lithium ion batteries in various missions, dedicated to transfer this technology to the industries to establish production facilities for producing lithium ion cells to cover the entire spectrum of power storage requirements of the country.

What The Govt Doing?

The Centre, with a target for ensuring that at least 30% of new vehicle registrations be electric by 2030, has focused on developing the value chain for batteries — cells — and for the same, it encourages local manufacturing of lithium-ion cells.

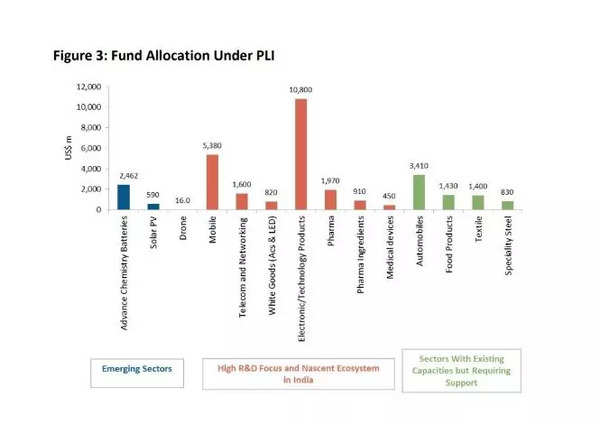

In April 2021, the Centre doubled import duty on lithium-ion cells to 10% and later announced a PLI scheme includes financial allocations for Advanced Chemistry Cell (ACC) batteries under the National Programme for Advanced Chemistry Cell (NPACC) and for automobiles and auto components with an emphasis on promoting local manufacturing.

Batteries Share in overall PLI scheme as per JMK Research analysis of Govt data: